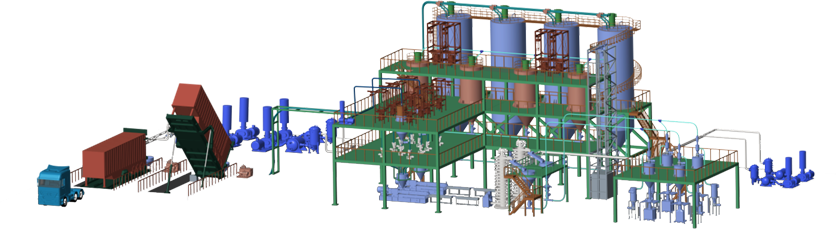

Compounding

Compounding refers to filling and mixing of minerals or additives into basic resin and through extruding to improve properties so as to expand application field. Compounding involves raw materials including basic resin, talc, CaCO3, fiber class, master batch and additives. The way of transferring all these raw materials into extruder should be carefully design based on material characteristics and recipe requirement. Finished product conveying design based on material properties, to avoid material abrasion and cross contamination.

Technical Advantages

-

01

Pretreatment of raw material

Drying, degassing, mixing and automatic proportioning

-

02

Finished products handling

Blending, degassing, dedusting, packing and automatic silo washing

-

03

Avoid cross-contamination

Automatic washing and drying system for pipe, silo and packing machine

-

04

Conveying of abrasive material

Conveying of abrasive material (e.g. material stuffed with fiber glass) Dense phase conveying and use of special bend

Scheme Value

Improve efficiency and save costs

Proprietary Automatic Unloading Technology for Containers and Bags

Reduction of breakage and residue of aggregates

Optimized pneumatic conveying system

Meet the requirements of clean production and GMP.

Design of Quick Disassembly Equipment and Modular Unit

Requirement for the accuracy of different main ingredients and accessories

Fully automatic batching system

Provides online recipe management and historical data query and download.

TEL:+86 20 83553890

TEL:+86 20 83553890