Plastic Processing

Plastic processing usually refers to a process that plastic in powder and pellet form is processed into plastic products. Thermoplastic processing methods have extrusion, injection molding, calendaring, blow molding and thermoforming, etc.; Thermosetting plastic processing methods have molding, transfer molding and injection molding. For large scale of plastic processing, for instance, spinning, non-woven, and double-wall corrugated pipe and film, raw materials include PET, Nylon, PE, PP, etc.

Technical Advantages

-

01

Raw material discharging

Automatic unloading of Small bag, carton, big bag, hopper truck, and bulk container

-

02

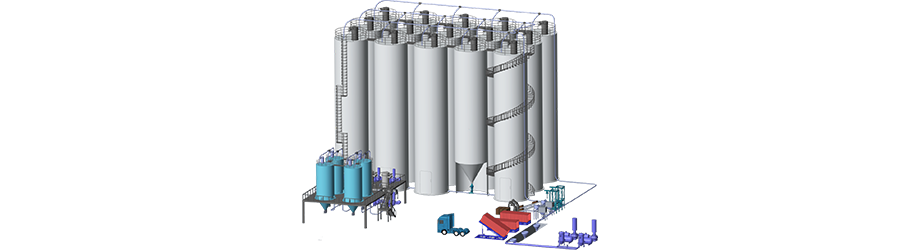

Raw material storage

Silo equipped with weighing system, and it can be linked to ERP

-

03

Raw material pretreatment

Drying, degassing, dedusting and recovery of the unqualified material

-

04

Waste and offcut material recovery

Collect, crush and recycle

Scheme Value

Improve efficiency and save costs

Proprietary Automatic Unloading Technology for Containers and Bags

Reduction of breakage and residue of aggregates

Optimized pneumatic conveying system

Meet the requirements of clean production and GMP.

Design of Quick Disassembly Equipment and Modular Unit

Requirement for the accuracy of different main ingredients and accessories

Fully automatic batching system

Provides online recipe management and historical data query and download.

Related Cases

First Quality Nonwovens (Wuxi) Co., Ltd.

Project:2015year,Vistamaxx pellets conveying system

Materials:Vistamaxx

Material properties:Tensile permanent deformation, Vicat softening point 48 ℃

Bayer Material Science

Project:2012year,PC/ABS Conveying/blending system

Materials:PC/ABS

Datang international (Duolun)

Project:2007year,460kt/a PP Pellets conveying system

Materials:pp

TEL:+86 20 83553890

TEL:+86 20 83553890