Duracell (China) Limited

Project Content

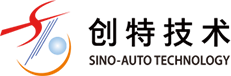

Project:2014year,powder processor modular assembly system

Materials:Graphite, Manganese dioxide, Etc,Capacity: 10-20t/h, Conveying distance: 60m, Dense phase conveying, Air velocity: 6.5m³/min,11m³ silo

System Features

● Material: graphite, manganese dioxide, etc;Capacity: 10-20t/h;Conveying distance: 60m;Dense phase conveying;Air velocity: 6.5m³/min;11m³ silo

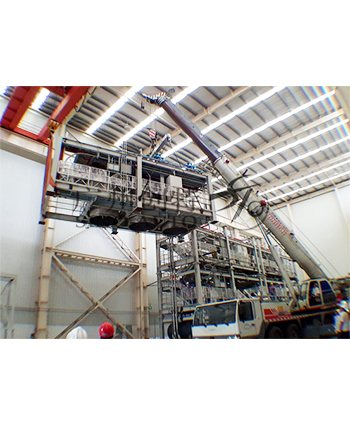

● Raw material area: super sack unloading ⇒ dense phase conveying to storage tanks ⇒ tank weighing ⇒ spiral proportioning ⇒ weighing tank ⇒ dense phase conveying to the main module ⇒ main module receiving tank

● Main module area: rework material blow tank ⇒ dense phase conveying to receiving tank; expansion joint unloading ⇒ roller conveyor

System Advantages

● Dense phase and low speed conveying, reduce the wear and tear of the pipe wall, small air flow, less selection of deduster, low energy consumption

● External bypass, automatic sequence of the emergency unbolck and pipe cleaning

● Design of vibration on the silo bottom effectively solved the problem of low material density and easy bypass

● In accordance with the requirements of the latest formula by Duracell, automatic high precision proportioning through spiral and weighing system

● Module design, reduce the site operation and the risk of site safety, shorten time of field operation, minimize the impact on the existing production order, reproducible, small occupation, compact layout

● Optimization of the dust collecting system effectively reduce dust production environment

● Module is easy to transport, land or shopping

Project Picture

Project Review

System feature:

● Capacity: >2t/h; Weighing system accuracy: 0.1%

● Make full use of height; Reasonable device for dosing; Accuracy orientation

Application Products

TEL:+86 20 83553890

TEL:+86 20 83553890