Application Brief

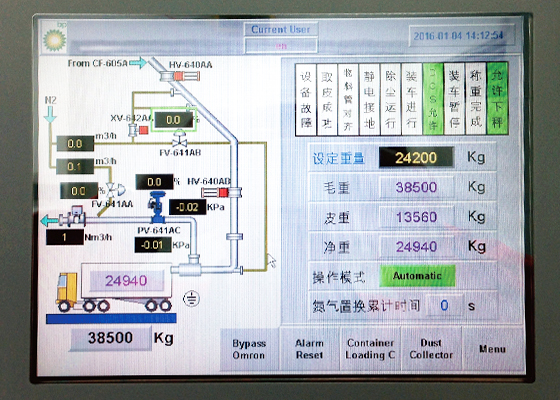

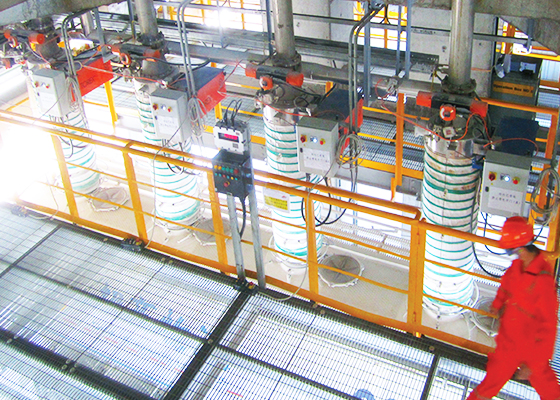

Currently, in most of plants, raw/finish products come or leave plant is in form of small bag package or big bag package. The cost of material loading and unloading takes a great proportion and it increase gradually along with the manpower cost growing.

Bulk container replaces small bag and big bag for material loading and unloading which can greatly save cost in logistic, packing material. And with bulk container advantage, products can be sold to overseas markets. The advantage is obvious in chemical industry, e.g. a 10kt/a plastic compounding plant, compared to small bag package of finished product, bulk container can help customer save 2 million RMB in logistics segment.

Catering for demand of market, Sino-Auto has developed several bulk container loading and unloading technology-S-Container®.

TEL:+86 20 83553890

TEL:+86 20 83553890